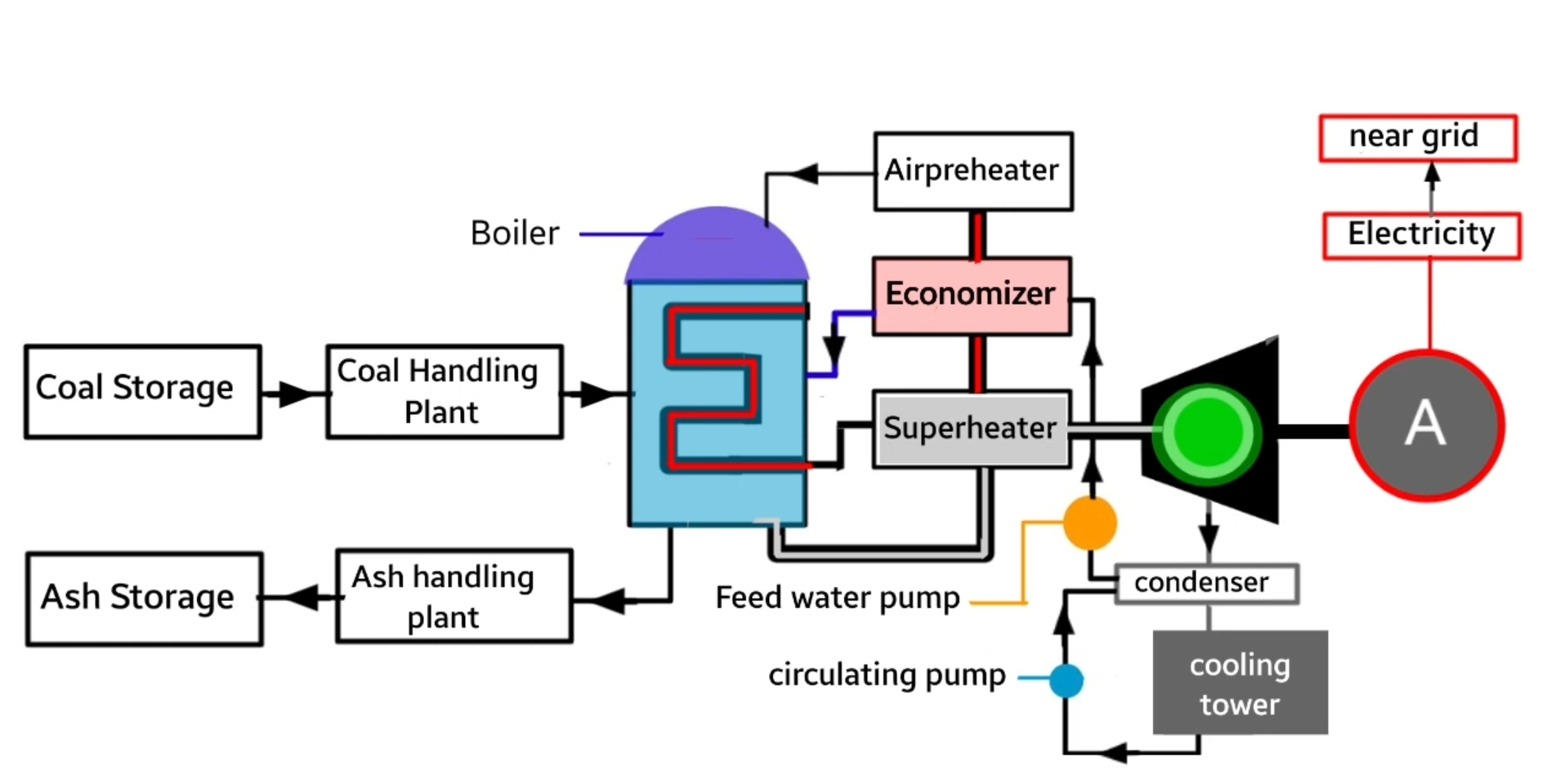

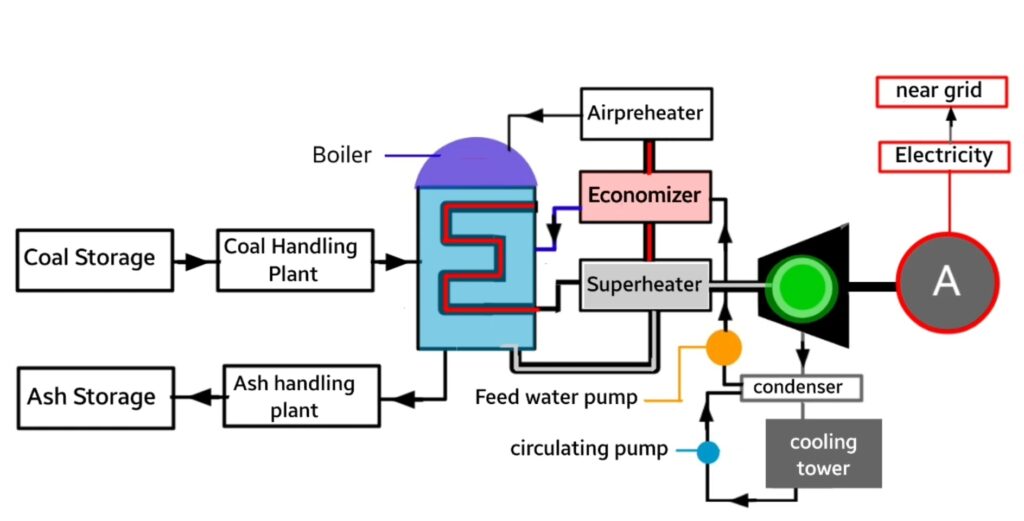

thermal power plant is a type of electricity generating station where heat energy converted into electrical energy. Thermal power plant consist with different main elements which play very important role in operation of generating electricity. It is non renewable energy Technology That depends on particular fuel that is coal.

In this article we will discuss working principle and important elements of the thermal power plant by the help of block diagram.

Thermal power plant working principle

Coal storage plant : we store the coal in coal handling plant from different part of the country that is transported by the rail and road root. We store the coal for continue operation of plant during transportation failure situation.

Coal handling plant : in coal handling plant coal converted into pulverization form, meaning of pulverization is crush or breaks the coal into very small pieces. Due to pulverization of coal its surface exposure increases that helps in rapid combustion. That’s why in coal handling plant coal is converted into pulverization form.

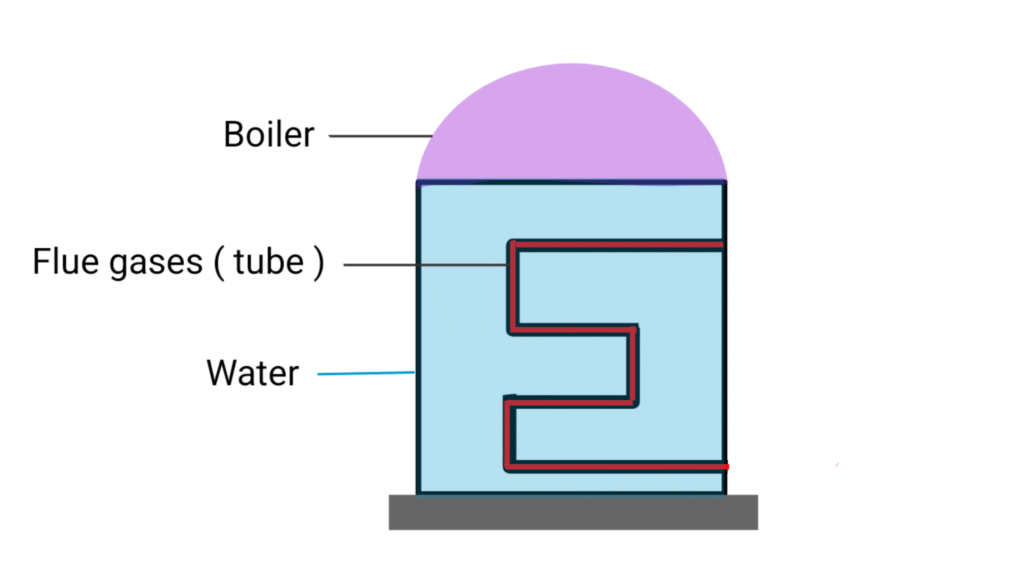

Boiler : boiler is the close vissel that is used to convert water into steam. We filled the purified water into boiler and supply the pulverized coal on the Furnace of boiler and pulverized coal burns in presence of Oxygen and produces hot flue gases. Generated hot flue gases flows in the tube inside the boiler.

There are two types of boiler fire tube boiler and water tube boiler I have consider fire tube boiler as you can see in the above diagram. In case of fire tube boiler fire or flue gases present inside the tube so it is called as fire tube boiler.

heat present in the tube due to flue gases, transfer in the water that filled inside the boiler. Water filled in the boiler converted in steam by receiving the heat from flue gases that present inside the hollow tube. After burning the coal remaining ashes stores in the ash storage through ash handling plant.

Superheater : generated steam from boiler goes into superheater where it converted into superheated steam. Main function of super heater is to convert weted steam into superheated steam. Since moisture contents when steam produces from the boiler and if moisture contain steam will strike on the turbine blade then life of turbine will be reduce so we convert moisture contain steam into superheated steam.

Turbine : turbine is the rotatory device that converts fluid flow like a (steam , water , air ) in to mechanical energy.

Super heated steam produced by superheater strikes on the turbine blades with high pressure. Due to kinetic energy of steam turbine starts to rotate that’s why this turbine is also known as steam prime mover because it convert kinetic energy of steam into mechanical energy. And to control the pressure of steam a valve is connected in path of superheated steam.

Alternator : alternator is the electrical machine that is used to convert mechanical energy into electrical energy.

Turbine shaft connected to alternator shaft so turbine rotates due to steam striking on the blades then alternator shaft also rotates. When alternator receives the mechanical energy then it convert mechanical energy into electrical energy.

alternator generates AC electrical energy and there voltage is increases by the help of step up transformer then High Voltage AC power transmitted to the near grid through transmission line. We increase the voltage of generated AC power to increase the overall efficiency of the power system.

Condenser : condenser is a device that is used to convert steam in to water, when superheated steam strikes on the turbine blade then pressure of superheated steam get reduced so low pressure steam flows in condenser through the tube and condenser condensed the low pressure steam in to water. And condensed water fall down from cooling tower to cool the water. Then that water transfer in the economizer.

Economizer : Economizer basically behave like heat exchanger, flue gases comes in economizer from superheater and water comes from cooling tower through the feed water pump, and water receives The Heat from flue gases or we can say heat exchange process is perform in the economizer. Then heated water transfer in the boiler. When we transfer heated water in the boiler then boiler rapidly converted the hot water into steam because heated water converted in steam rapidly instead of cool water.

Economizer increases the over all efficiency of the system by reducing the stress of the boiler. After that flue gases flows into air preheater.

Air preheater : Air preheater suck the air from atmosphere by the help of forced draft fan and since it is located in the path of flue gases so heat of fuel gases transfer in the air and Air gets heated and that heated air supplies in the grate of boiler where combustion takes place. So overall efficiency of the system increases due to function of air preheater.

After that remaining flue gases and smokes exit in air through chimney. Height of chimney remain very large to protect the local area from air pollution. Same process repeats continuously and produces electricity.

Thus thermal power plant or station works and generate the electrical energy by the help of coal.

Other Topics

- 3 phase induction motor

- Alternator working principle

- Synchronous motor

- PMSM motor

- Universal motor

- DC motor working principle

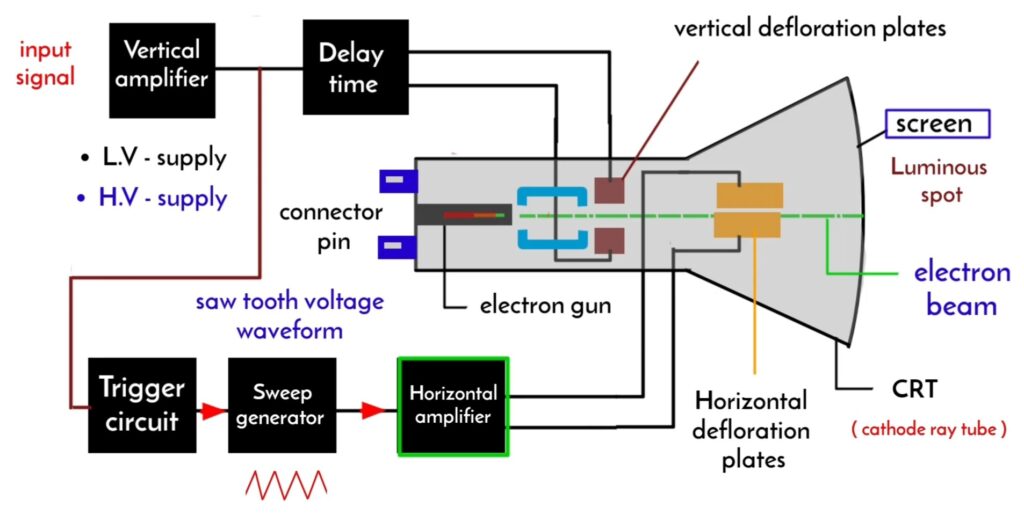

cathode ray oscilloscope working principle with diagram

CRO – stands for cathode ray oscilloscope that is type of device or instrument which…

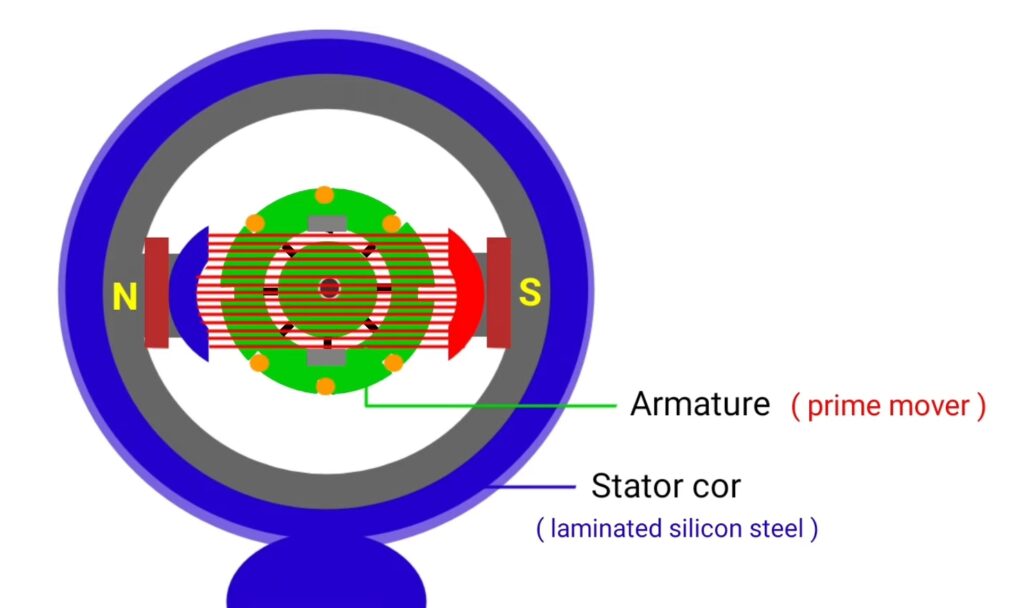

What is the working principle of a DC generator

DC generator is the electrical machine that is used to convert mechanical energy into dc…

What is meant by thermal power plant

thermal power plant is a type of electricity generating station where heat energy converted into…

Repulsion motor principle

Repulsion motor is the special purpose machine that converts electrical energy into mechanical energy where…

Commutation in dc machine diagram

Commutation in DC machine is the process by which AC current induced in the armature…

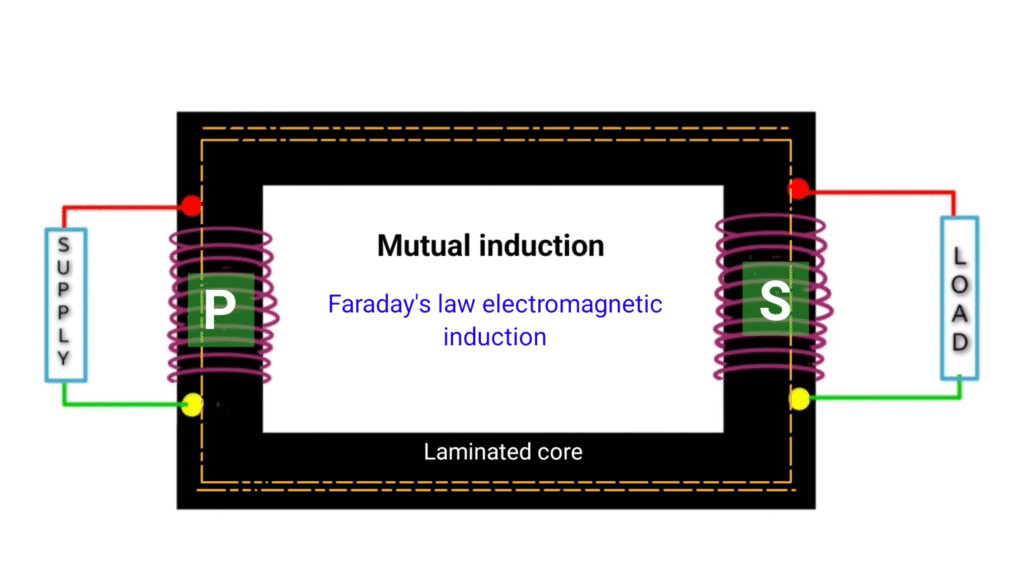

What is the working principle of single phase transformer

Single phase transformer is the static device or machine that is used to increase or…