Armature winding classified in to two types lap winding and wave winding. If we talk about armature winding it is very important part of the rotating machine where energy conversion process performs.

in case of generator mechanical energy converted into electrical energy and in case of motor electrical energy converted into mechanical energy where we use either lap winding and wave winding on armature

Lap winding

- Lap winding is used for requirement of low voltage and high current.

- in lap winding number of parallel path equal to number of poles that is ( A = P )

- meaning of parallel path is total number of path by which current will flow between the terminal and it is denoted by (A).

different types of lap winding

- Simplex lap winding : in simplex lap winding number of parallel path is equal to the number of pole ( A = P )

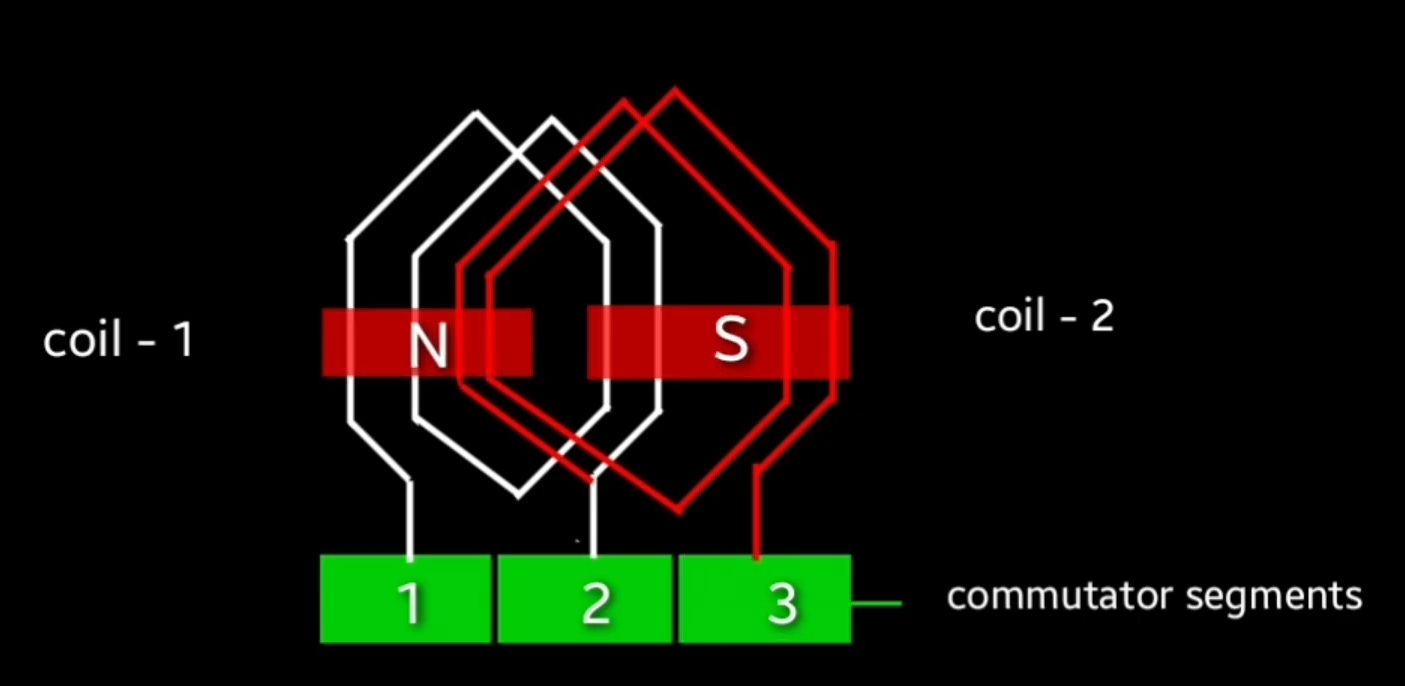

(coil – 2) will start from the ending point of (coil – 1) , mean next coin will start from the end point of first coil.

2. Duplex lap winding : duplex lap winding number of parallel path of winding is twice with respect to poles. ( A = 2P )

as you can see in the diagram here there are three commutator segments , turning of first coil started from the commutator segment -1 and after two turns of coil it ends on the commutator segment – 2 And turning of 2nd coil starts from the commutator segment – 2 and after two turns of the coil It ends on the commutator segment – 3 and alternate magnetic pole developed on the coil.

3. Triplex lap winding : in triplex lap winding number of parallel path is three times of poles . ( A = 3P )

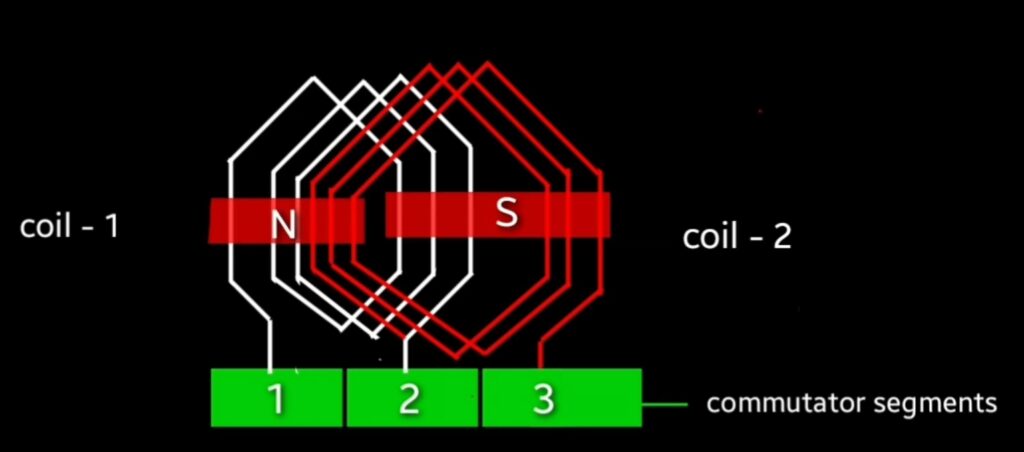

as you can see in the above diagram there are total three commutator segment shown in the figure first coil started from the committed segment 1 and after 3 terms of the coil It ends on the commutator segment – 2 and second coil starts from the commutator segment -2 or we can say end of the first coil and after two turns of the second coil It ends on the commutator segment – 3. And this process will continue on next commutator segments.

NOTE ( lap winding and wave winding )

- Lap winding is used in that type of application where need of or we can say requirement of low voltage and high current operation at that place generally we use lap winding.

- in case of lap winding Low EMF induces compare to wave winding

- if we provide lap winding in any rotating machine then cost of machine increases .

Wave winding

in wave winding only two parallel path are provided between the negative and positive brush. This type of winding is used where we have requirement of high voltage and low current.

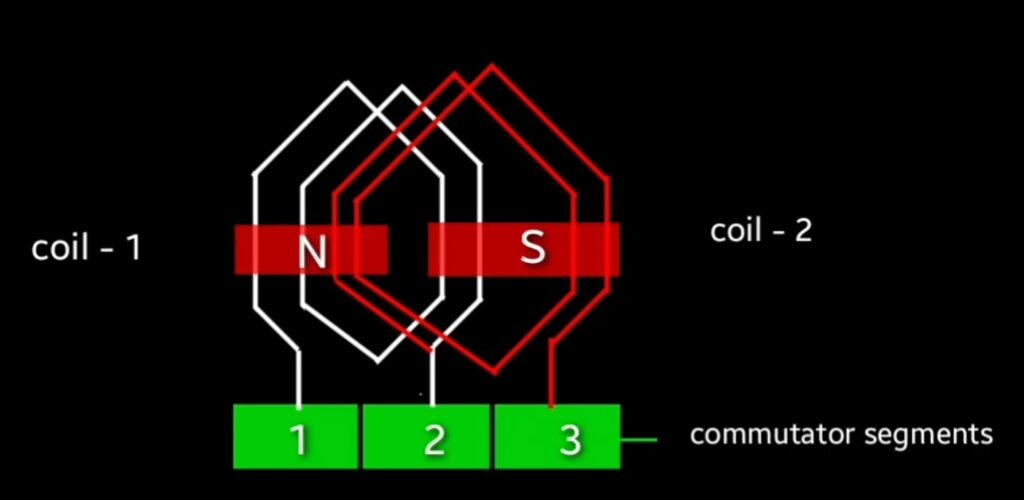

as you can see in the above diagram here coil – 1 is placed on commutator segments and coil – 2 started from end point of coil – 1 and ends on next commutator segment.

starting pole of (coil – 1) and starting pole of (coil – 2) remain always same. And end point of the first coil and starting point of the second coil will be always different. In case of wave winding coils are connected in series so it is also called as series winding.

in case of wave winding number of brushes is equal to the number of parallel path ( B = 2 ) .

Wave winding is categorised into two types

- retrogressive winding

- Progressive winding

Full pitch coil

when the angular distance between coil to sides is electrically 180° then it is called as full pitch coil

Net voltage = EC1 – EC2 = +E – (-E) , Net voltage = 2E

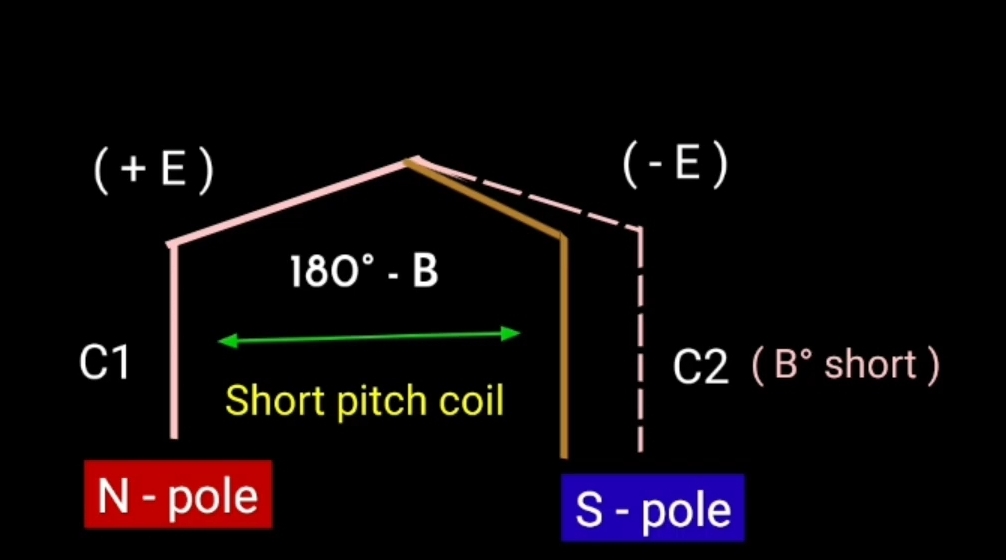

Short pitch coil

if the angular distance between two coil sides are less than the pole pitch then it is called as short pitch or fractional coil.

to understand the short pitch coil we consider two sides of the coil as you can see in the diagram second side of the coil is B° shorted . So distance between both side of the coil will be (180° – B) , where B – short pitch angle.

Conclusion : so this is all about lap winding and wave winding the main difference between lap winding and wave winding , lap winding is used for the application of high current and low voltage whereas wave winding is used for the application of high voltage and low current. so i hope you will get detail about lap winding and wave winding. in previous article i have describe about different machine topics and this lecture totally based on lap winding and wave winding