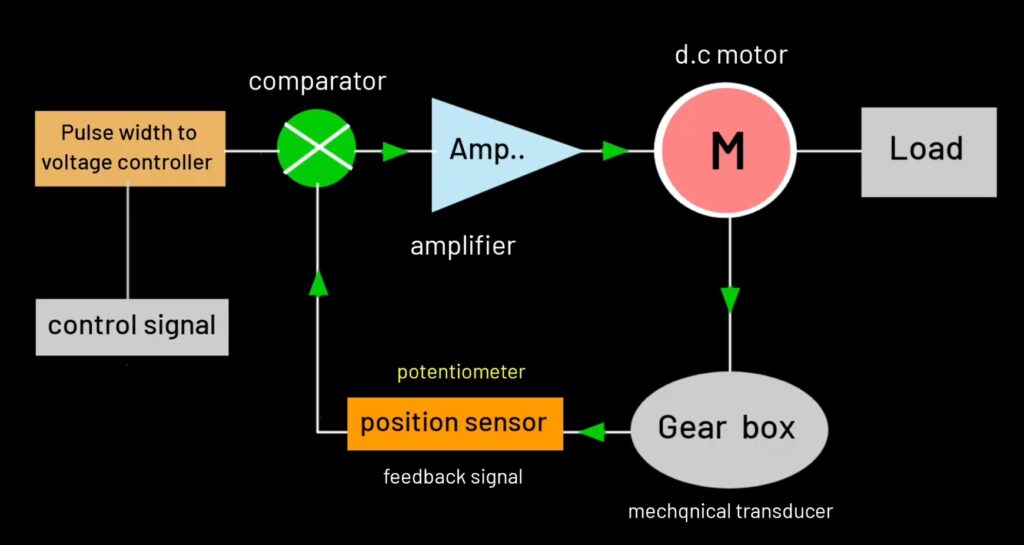

dc servo motor is type of special machine which produces mechanical power like position velocity acceleration by taking DC power is known as dc servo motor. This type of motor is generally used for the quick start and stop the load like machine computer by numerical control. DC servo motor consist with different main elements that shown in the block diagram below.

Construction of dc servo motor

In this system DC motor is used that connected to the Servo mechanism. And load is connected to the motor shaft like Fan , industrial load .. etc that simply connected to the shaft of DC motor.

in this system gearbox behave like mechanical transducer that convert the motor output in motion , velocity , acceleration according to particular application.

Position sensor : position sensor uses potentiometer that work like feedback signal, potentiometer produces the voltage signal and motor shaft remain proportional to absolute angle. Mean position sensor have main function to detect the angle of rotor shaft.

Comparator : computer is a device that is used to produce error signal by comparing position sensor value and reference value and produced error signal sends to the amplifier.

here a closed system becomes with the gearbox , position sensor and amplifier. And due to this close loop system DC motor produces accurate output.

Amplifier : main function of amplifier is to read the error signal and according to that error signal it control the input power of DC motor so that motor can produce accurate output. It performs like proportional controller.

Control signal : when position sensor produces the feedback signal then control signal receives the feedback signal produced by position sensor and according to that feedback signal it produces PWM signal and amplifier amplifies the pwm signal and sends to the motor input for precise control and motor rotates at the particular angle according to given instruction by the amplifier.

Mean by the help of close loop system DC servo motor works and obtain the velocity , acceleration , and exact angle according to application.

dc servo motor working principle

when input signal apply in DC motor then shaft and gear rotates and output of the gearbox fed into position sensor that uses Potentiometer so nobes of potentiometer turns and varies the resistance and voltage. And due to change in resistance voltage of the DC motor also changes , error single generates

error signal fed in to the comparator and it compare the value between error signal and reference value. And according to result of compare, PWM signal generates and amplifier amplify the PWM signal ans fed in to motor input so that motor can produce precise and accurate output. Thus dc servo motor works

Characteristics of dc servo motor

- construction of DC servo motor is just like permanent magnet DC motor.

- Speed control in this type of motor is done by controlling the armature voltage.

- it designed with high armature resistance.

- DC sarvo Motors are design to provide quick torque response

- when we change the armature resistance of the Servo Motor then speed of motor changes quickly.

Conclusion : DC servo motor is designed to respond control signals produced by amplifier that embedded into the Servo mechanism for precise and accurate Motion Control. In DC servo motors we can control the speed of motor by using two method that is either field control aur armature control. In case of field control method motor response is faster due to direct armature current or voltage adjustments that make it suitable for that type of application where ideal for requesting fast response time.

What is Servo mechanism ?

Servo mechanism is a close loop control system that uses feedback to control the position of motor shaft or connected load so that it can precisely control the position , speed and torque of the particular device.

Key components of servo mechanism.

Motor : it is type of machine that main function is to convert electrical energy into mechanical motion.

Controller : controller is a semiconductor device that receives the feedback from position sensor or feedback mechanism and according to feedback it controls the motor speed or motor shaft angle according to requirement.

Feedback mechanism : feedback mechanism monitors the output of close loop system continuously and according to requirement produces feedback signal and sends to the controller. As feedback mechanism if we can use sensors such as encoder that measure the position or speed of the motor usually DC motor is used.

any of the motor can be converted into Servo Motor by connecting the motor with Servo mechanism but usually we use or prefer DC motor that connected to the servo mechanism and called as Servo Motor that can be either DC Servo Motor or AC Servo Motor.

Applications

- for the movement of robotic arm and their leg DC servo motors are used, play very important roll in the field of robotics.

- For precise and accurate position DC servo motor is used as positioning tools in CNC machine.

- this type of motor is used in the Industrial Automation for controlling process during manufacturing of different goods.

- they are used in Aircraft control for controlling surface and actuators in aircraft.

- These motors are used in electronic devices manufacturing like different Semiconductor devices for their precise motion and various mechanism helps to manufacture the parts of electronic devices accurately.

Advantages

- DC servo motor uses closed loop feedback system that make it highly accurate and precise control.

- they are used for fine grained control that make it suitable for that type of application where requiring micro movement or intricate Positioning.

- DC servo motor provides high torque at low speed which is crucial for that application where we have to maintain consistent torque at low RPM.

- this type of motor have high reliability and long durability

- this motor provides for quadrant operation that allows for both forward and reverse rotation and braking.

Disadvantages

- generally we used DC motor that connected to servo mechanise so due to carbon brushes in DC motor their lifespan is limited.

- Servo motor has Complex control system because it have requirement of external accessories like servo mechanism that embedded with controller encoder potentiometer etc..

- watch video