Commutation in DC machine is the process by which AC current induced in the armature winding of DC generator , converted into DC is known as commutation process or commutation in dc machine. Commutator is the main element of commutation process that is a rotating metallic ring. In this process commutator behave like mechanical rectifier to convert induced AC current into DC current.

Process of commutation in dc machine

commutator is the main element of armature that play very important role during commutation in dc machine or commutation process,

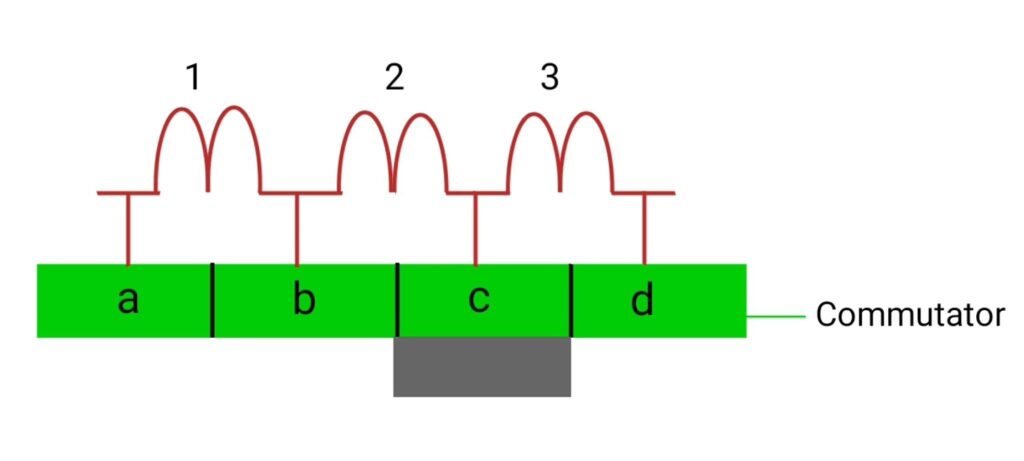

commutator is the metallic ring that consist with different segments and segments are insulated by the coating of mica. To understand the communication process or commutation in dc machine we spread or open the commutator ring that shown in the above diagram. Carbon brush is attached with the commutator segment that remain stationery and when segments rotate than position of carbon brush changes.

we consider three main position of brush to understand the concept of commutation in dc machine

Case – 1 : in first case carbon brushes attached completely with commutator segment-C and direction of current in coil like this.

in this condition current will flow from coil-3 and coil-2 to the segment-C and brush will collect that current so ( i + i = 2i ) so in first case we get (2i) current in output.

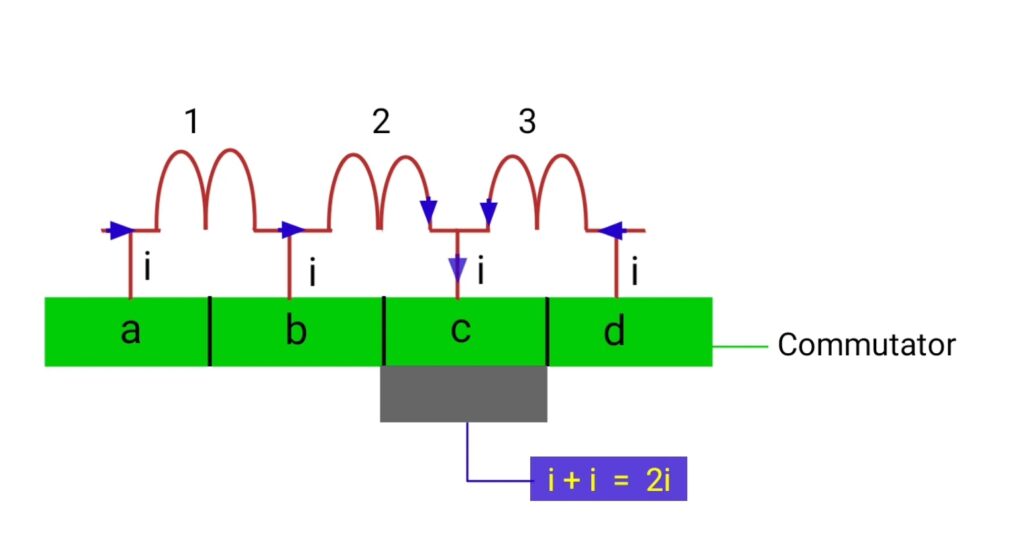

Case – 2 : in second case carbon brush shifted at middle portion of two commutator (B & C) .

Half portion of brush attached with segment-B and other half portion of brush present on segment-C. In this condition current will flow through both segment becouse brush is completing the circuit with both segment. This condition of brush with segments is called as short circuit condition

Since each segment of commutator insulated by mica but in second case conducting carbon brush is attached with segment-B and segment-C so both segment will be short.

in this condition current will not flow through coil-2 , incoming current from coil-1 and coil-3 is flowing through segment (B & C) . No any current flows in coil-2 , becouse property of electric current it always finds low resistance path or shortest path to flow. Shortest path has low resistance that’s why incoming current from coil-1 and coil-3 flow through segment (B & C) instead of coil-2.

So in second case brush collects (i) current from segment-b and (i) current from segment-c so total collected current ( i + i = 2i).

Short circuit condition occurs in 2nd case that is also known as commutation period because at this time current get reverse. During short circuit condition reactance voltage develops due to inductive property and reversal of current. Due to reactance voltage , spark creates in between carbon brush and commutator segment.

Due to sparking an ideal or good commutation don’t occurs. So to reduce the reactance voltage we use compensating winding and high resistance carbon brushes. How can we achieve an ideal commutation will learn in next article.

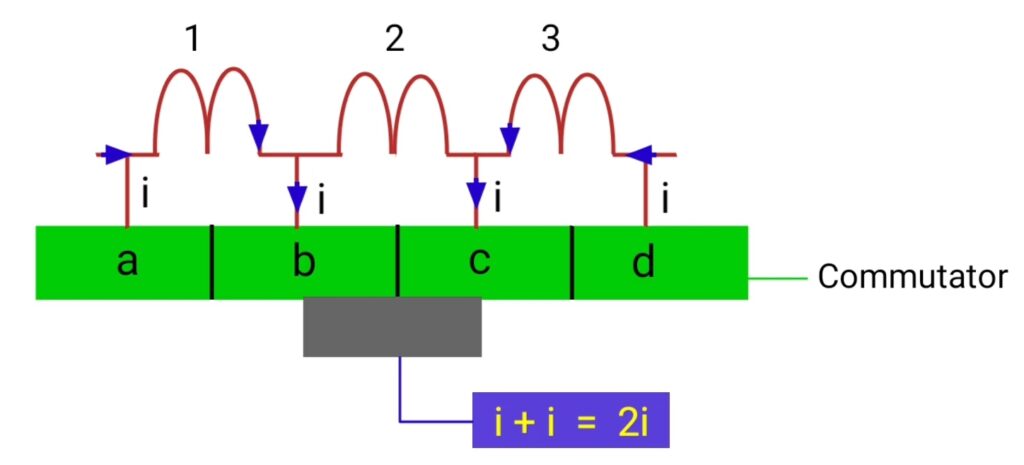

Case – 3 : armature rotates clockwise and carbon brush shifted at next segment i.e.. completely at segment-b like first case.

So here also current will flow from coil-1 and coil-2 to the segment-(b) and brush will collect 2i current from commutator segment-b. So in third case also same current collected by the brush. ( i + i = 2i )

Since we have changed the position of brush 3 times and we got same output current on carbon brush and if we change the position of brush more than 3 times then same current will obtain at carbon brush. So we can say induced ac current in armature winding is converting in dc current by the process of commutation in dc machine .

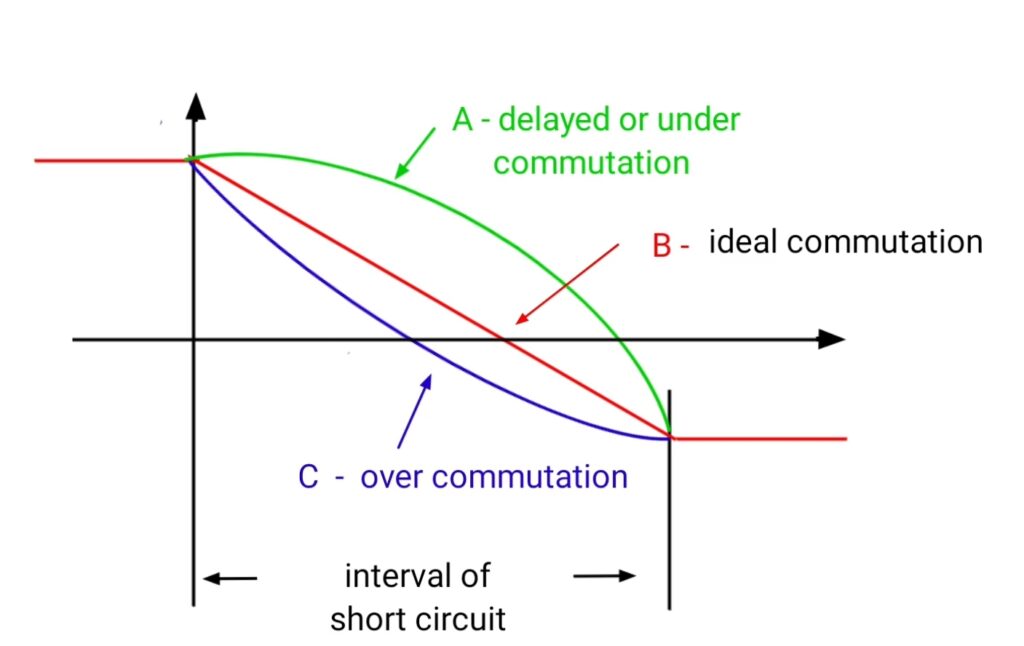

Here this graph is representing commutation period. or commutation in dc machine

Curve-B is showing an ideal commutation that is in between

(+i to -i ) when current changes linearly then this type of commutation is known as ideal commutation also it is known as straight line commutation.

Curve – A is showing delay or under commutation. Curve – C is showing over commutation. Please reduce the reference

to reduce reactance voltage aur sparking at brush there are three methods are used or improving the communication in DC machine

- resistance commutation

- EMF commutation

- by using compensating winding

Polarity of current in armature winding

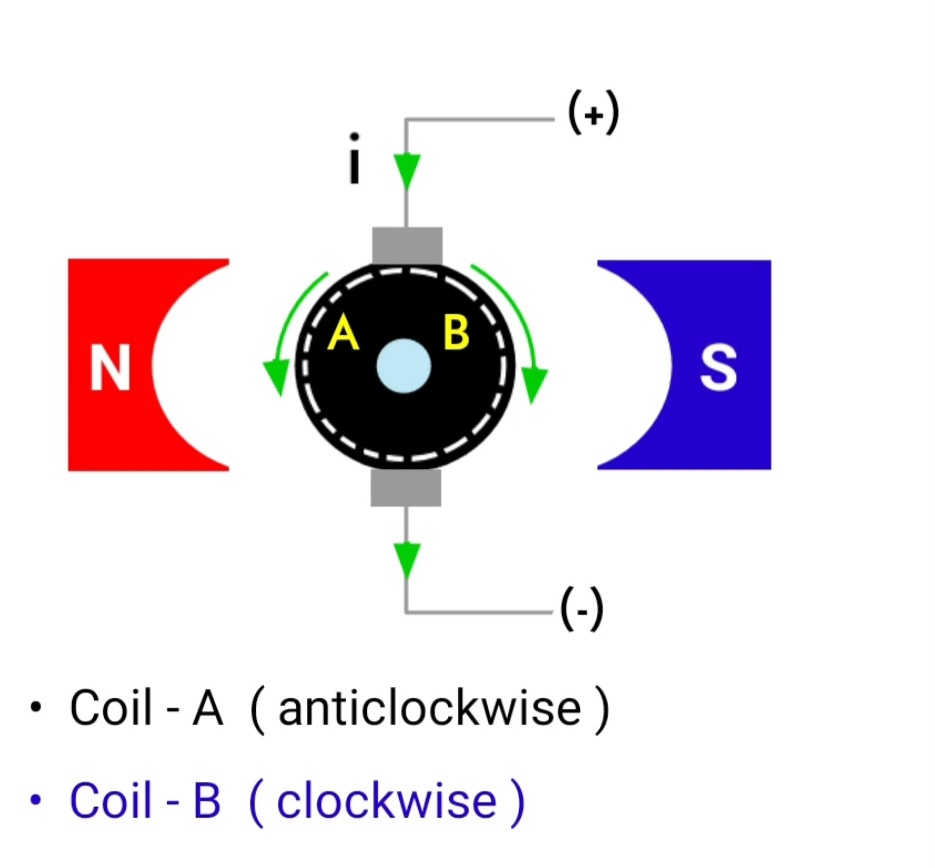

Suppose an armature of dc machine placed in magnetic field and carbon brushes are attached to the armature.

Attached carbon brushes are stationery that don’t rotates with armature. Suppose (i) current is entering from the positive terminal and travel through the negative terminal. Consider any two coil of the armature (A & B) to check the polarity of current. So as you can see in the above diagram current will flow through the coil A and B like this.

direction of current in coil-A is anticlockwise and direction of current in coil-B is clockwise.

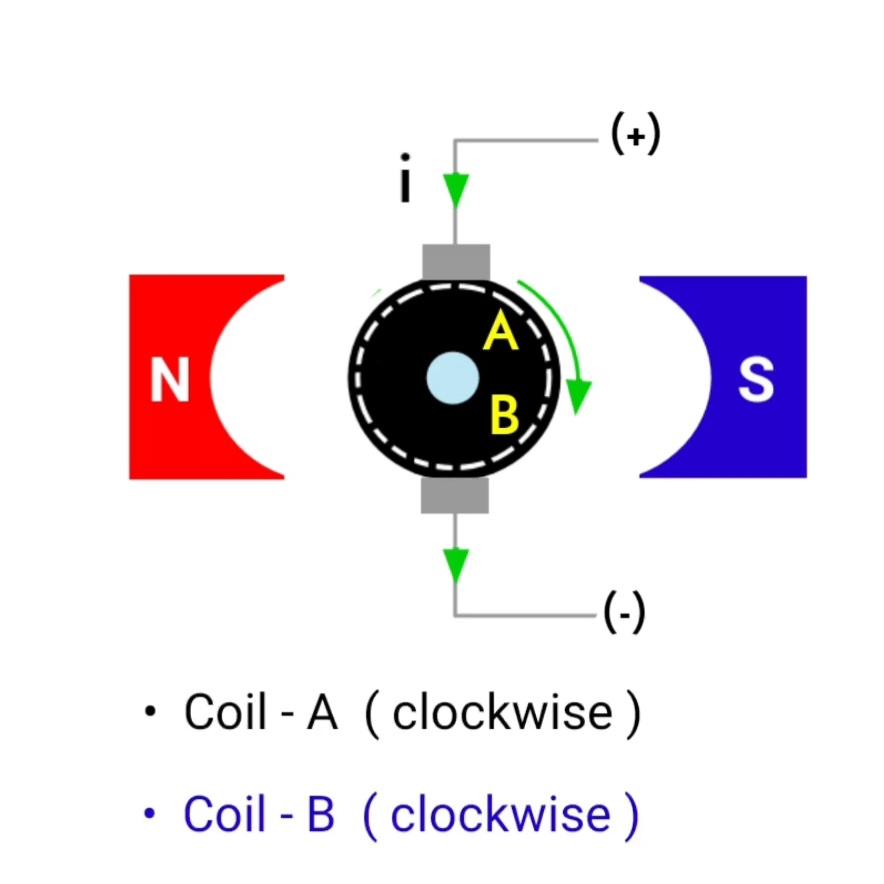

since armature is rotating in clockwise direction so we are assuming that position of coil A and B will be like this after few moment that is shown in the diagram below.

at this moment direction of current in both coil is clockwise , this is main concept of commutation process or commutation in dc machine, Few moment before direction of current on coil-A was anticlockwise and when armature rotates and cross the brush axis then direction of current on coil-A is clockwise. So this reversal of current in DC machine is called as commutation process or commutation in dc machine.