Permanent magnet synchronous motor is type of AC synchronous motor which converts electrical energy into mechanical energy. Construction of PMSM motor is different from normal AC synchronous motor in PMSM motor we use permanent magnet that increases the efficiency of the machine.

Construction of permanent magnet synchronous motor

permanent magnet synchronous motor consists with different main parts

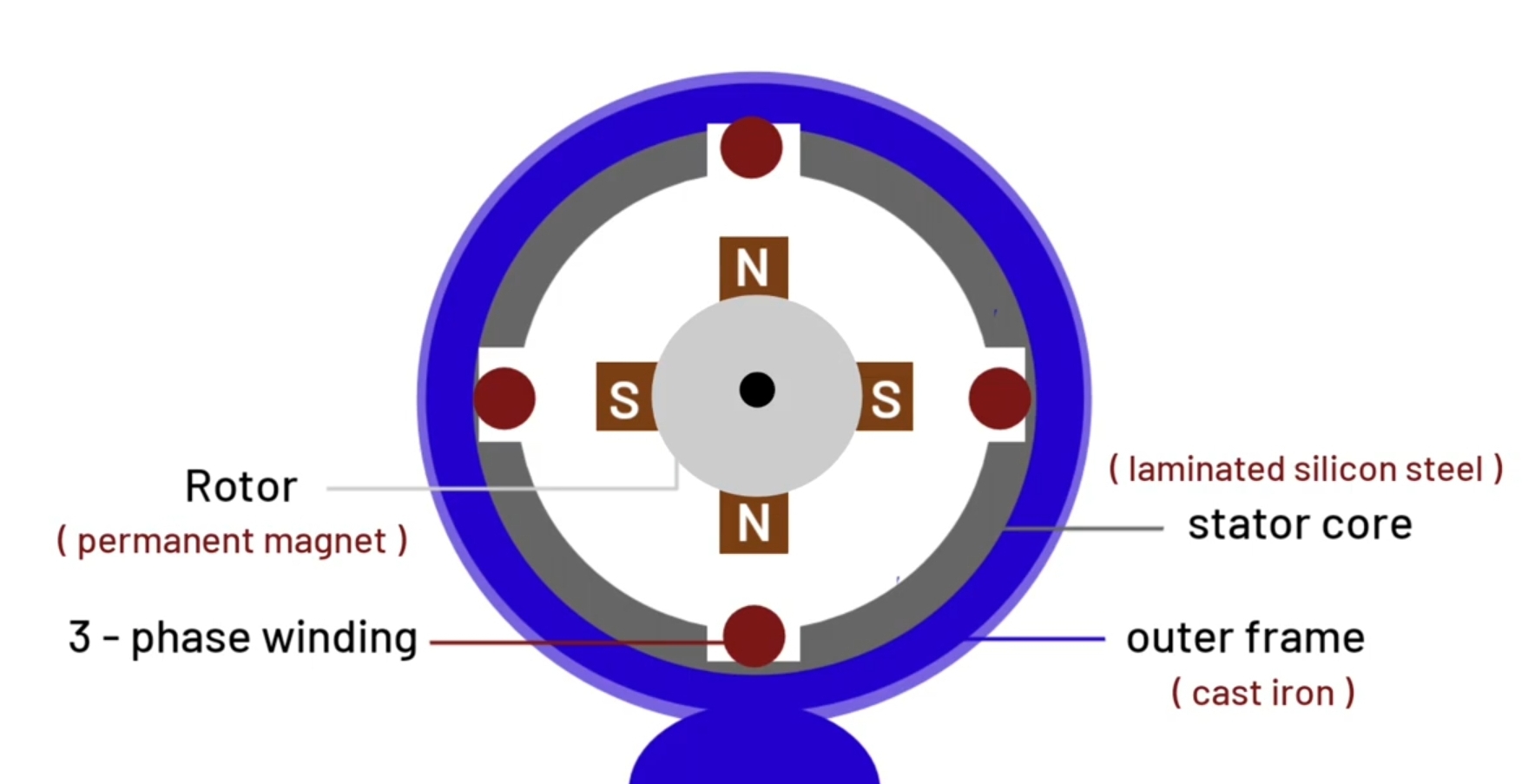

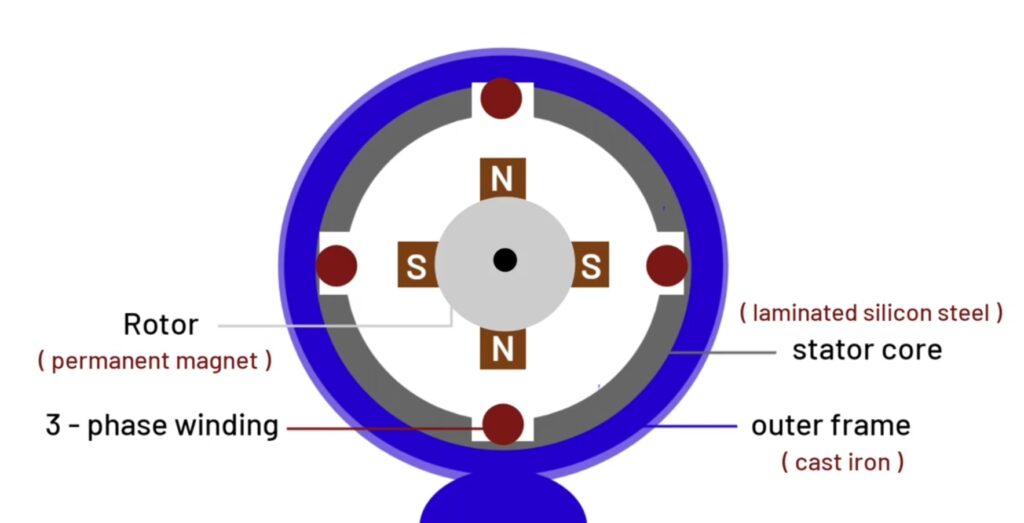

Stator : Stator is the stationary part of the permanent magnet synchronous motor.

Stator core : stator core is made up of laminated silicon Steel , we use Silicon Steel material to increase the efficiency of the machine because high permeability property that provide lower reluctance path for the magnetic field lines. And we provide lamination or laminated core to reduce electrical losses like Eddy current loss .

Stator frame : Frame is made up of cast iron that is used to protect internal assembly of permanent magnet synchronous motor frame provides mechanical support and protection from the environmental impact.

Stator winding : slots are present at the inner portion of stator Core where 3 phase copper winding is placed either in star or delta connection. we use copper material for winding due to their good electrical conductivity.

Rotor : rotor of permanent magnet synchronous motor is rotating element that is made up of permanent magnet.

as a rotor we are using permanent magnet so magnetic polarity will be constant that is S-pole and N-pole. And there are no need of winding due to permanent magnet. And due to absence of winding on rotor commutator and brushes are not required because commutator and brushes are used for exciting the rotor winding but in case of PMSM motor we are not using rotar winding so commutator and brushes will be absent.

magnetic material that will use for making rotor that should high Cohesive force. It’s rotor can be design of two types silent pole permanent magnet rotor and non salient pole permanent magnet rotor.

in salient pole permanent magnet rotor, poles projected outward or we can say projected towards the stator winding and due to projecting poles it is called as salient pole rotor and in case of non salient pole rotor have cylindrical shape and poles exist inward.

Working principle of permanent magnet synchronous motor

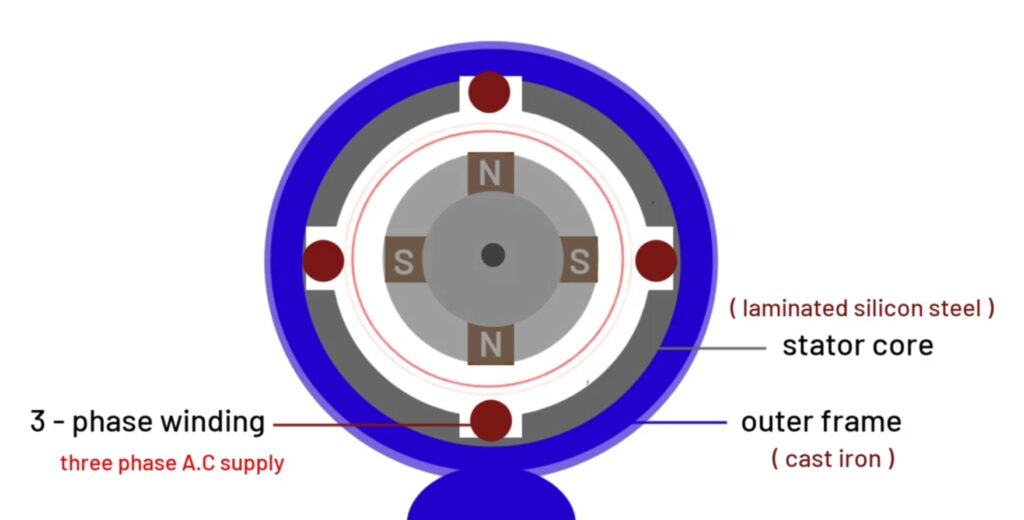

first of all we give three phase AC supply in stator winding. Since rotor winding is placed at an angle of 120 degree and due to three phase winding rotating magnetic field (RMF) produces in the air gap of rotor and stator that rotates at synchronous speed. Synchronous speed equation is given by ( Ns = 120F/P ).

- Ns – synchronous speed

- F – frequency

- P – number of poles

mean in case of PMSM motor there are no any changing in the construction of stator it’s stator is just like normal three phase induction motor.

as well as we rotate the rotar of PMSM motor with the help of external means or we can say external prime mover like DC motor or induction motor. When speed of rotor reaches synchronous speed with the help of external prime mover , generally we use variable frequency drive and Servo drive to start the machine or reaches the speed of pmsm rotor at synchronous speed. And external prime mover get removed after reaches the rotor speed at synchronous speed.

when rotor speed (Nr) will be equal to synchronous speed or (RMF) then interlocking tag place , opposite polarity of stator and rotar get interlock like normal synchronous motor.

and rotor continue rotates at synchronous speed with rotating magnetic field (RMF)

we use external mean to start the PMSM motor so this motor is not a self start motor like conventional AC synchronous motor.

Conclusion

working principle of permanent magnet synchronous motor (PMSM) motor and conventional synchronous motor is almost same the main difference between both type of motor , permanent magnet synchronous motor (PMSM) motor uses permanent magnet rotar and conventional synchronous motor uses copper winding on rotor that innergize by the separate supply with the help of commutator and carbon brushes.