plugging braking is the technique by which we brakes the electric motors. Plugging is the very fast technique of braking in which supply voltage get reverse. Plugging braking is also known as reverse braking , this technique is used in emergency situation for rapid deceleration .

plugging braking system

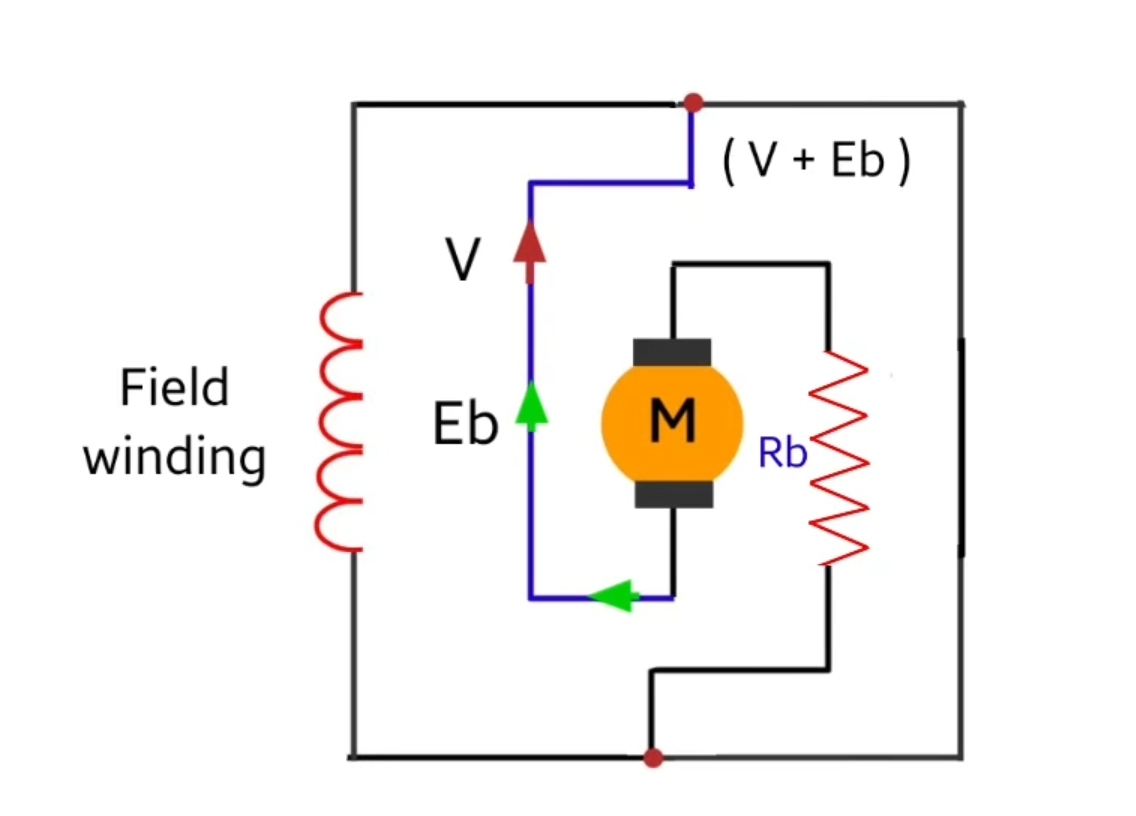

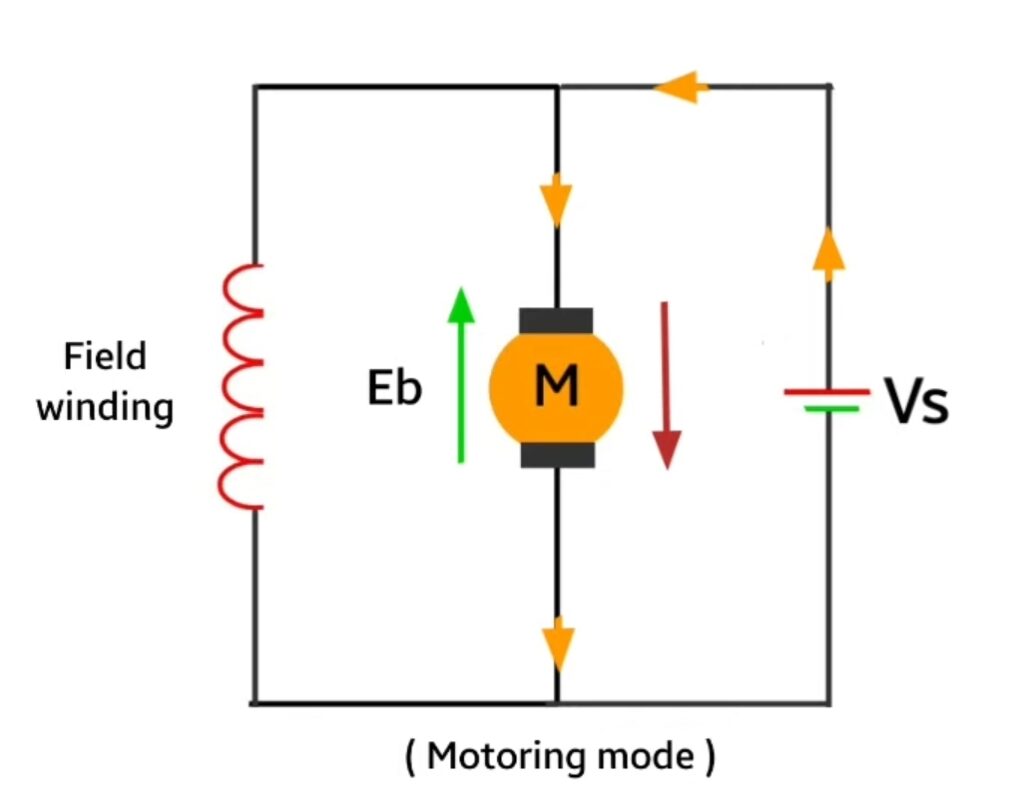

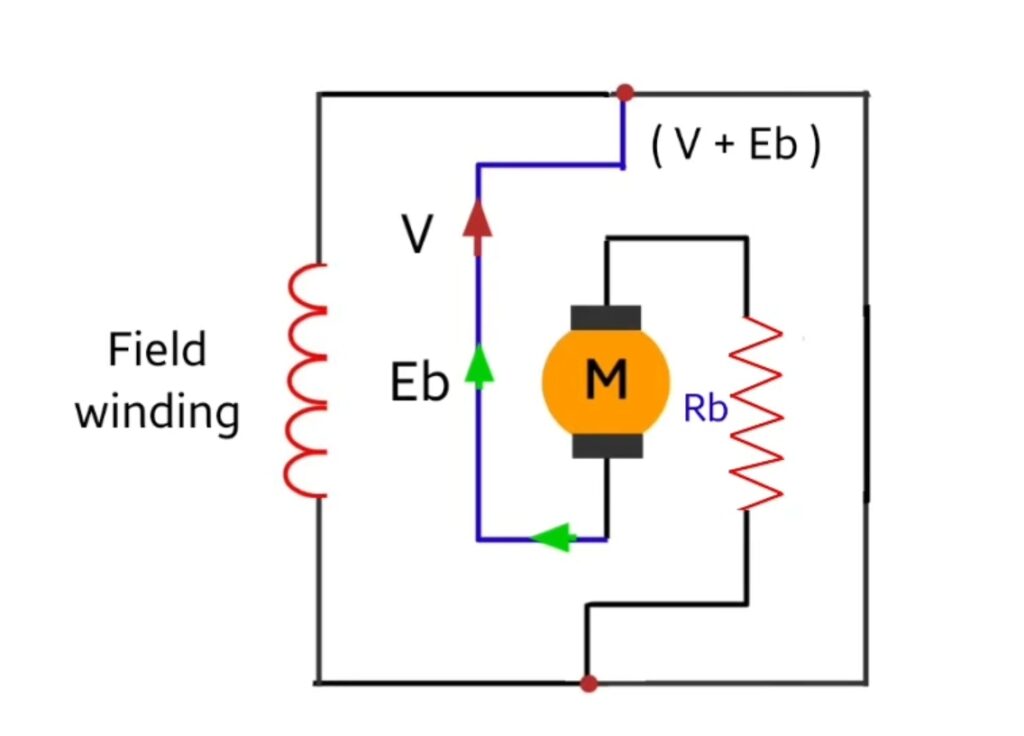

here it is armature of DC motor and it is field winding this circuit diagram is showing motoring mode , during motoring condition of DC motor back EMF (Eb) remain opposite to the supply voltage (v) as you can see in the diagram back EMF and supply voltage both the direction are opposite.

to perform braking operation we interchange the armature terminal and due to interchange the armature terminal , supply voltage and back EMF, now both are flow in the same direction

a resistance (Rb) is connected to the armature terminal that is known as braking resistance. Now we will understand what is the effect of interchanging armature terminal.

during normal condition of DC motor rotor rotates in clockwise direction but after interchanging the armature terminal , torque acts on armature in anticlockwise direction because the direction of supply voltage has reversed. When reverse torque apply on the armature rotor speed becomes zero when rotor speed become zero we disconnect the supply voltage from circuit.

if we will not remove supply voltage from the circuit then armature will start to rotate in reverse direction that’s why when reverse torque apply on the armature and armature speed becomes zero then we remove supply voltage from the circuit.

Plugging braking of induction motor

To apply plugging braking in 3 phase induction motor we reverse the phase sequence , to reverse the phase sequence we interchange the any two terminal of three phase induction motor , due to this rotating magnetic field of three phase induction motor get reverse in air gap of stator and rotor.

In working principle of three phase induction motor we have already study that when three phase AC supply provided in field winding that placed on stator at an angle of 120° , rotating magnetic field produces in the air gap of rotor and stator and in case of plugging braking we interchange any two input terminal of 3 phase induction motor as a result produced rotating magnetic field get reverse and due to reverse rotating magnetic field applied torque on rotor also get reverse so rotor quickly stops. Thus we apply plugging braking in 3 phase induction motor.

Normal slip : (Sn = Ns – Nr/Ns )

Braking slip : ( Sb = Ns + Nr/Ns )

Conclusion

plugging braking operates due to the supply terminal of the motor are reversed either through contactor or solid state switch , due to reversal of supply applied torque on motor also get reverse, reverse torque opposes the speed of motor and finally stops the speed of motor

Need of braking

- to limit the speed of drive within the safe limit.

- accurate us stopping in lift and different machine tools.

- for emergency stops in order to prevent accident.

- to stop the motor quickly and reverse it.

types of breaking system

Electrical braking : the kinetic energy of rotating part is converted into electrical energy.

This electrical energy dissipated in the resistance or return to the supply by changing the electrical connection of motor.

Regenerative braking : the motor is operated as generator, the kinetic energy of the rotating part of the motor is converted into electrical energy. This electrical energy then return to the supply. The necessary condition for the regenerative breaking is ( Eb > Vs ). After that armature current get reversed and the motor act as generator.

Dynamic braking : the armature of DC motor is disconnected from the supply and connected across braking resistance (Rb). The field winding remain connected to the supply hence the motor now work as generator and produces braking torque.