DC motor is the electrical machine that converts DC electrical energy into mechanical energy. In this article you will get dc motor working principle and construction detail explanation.

construction of dc motor

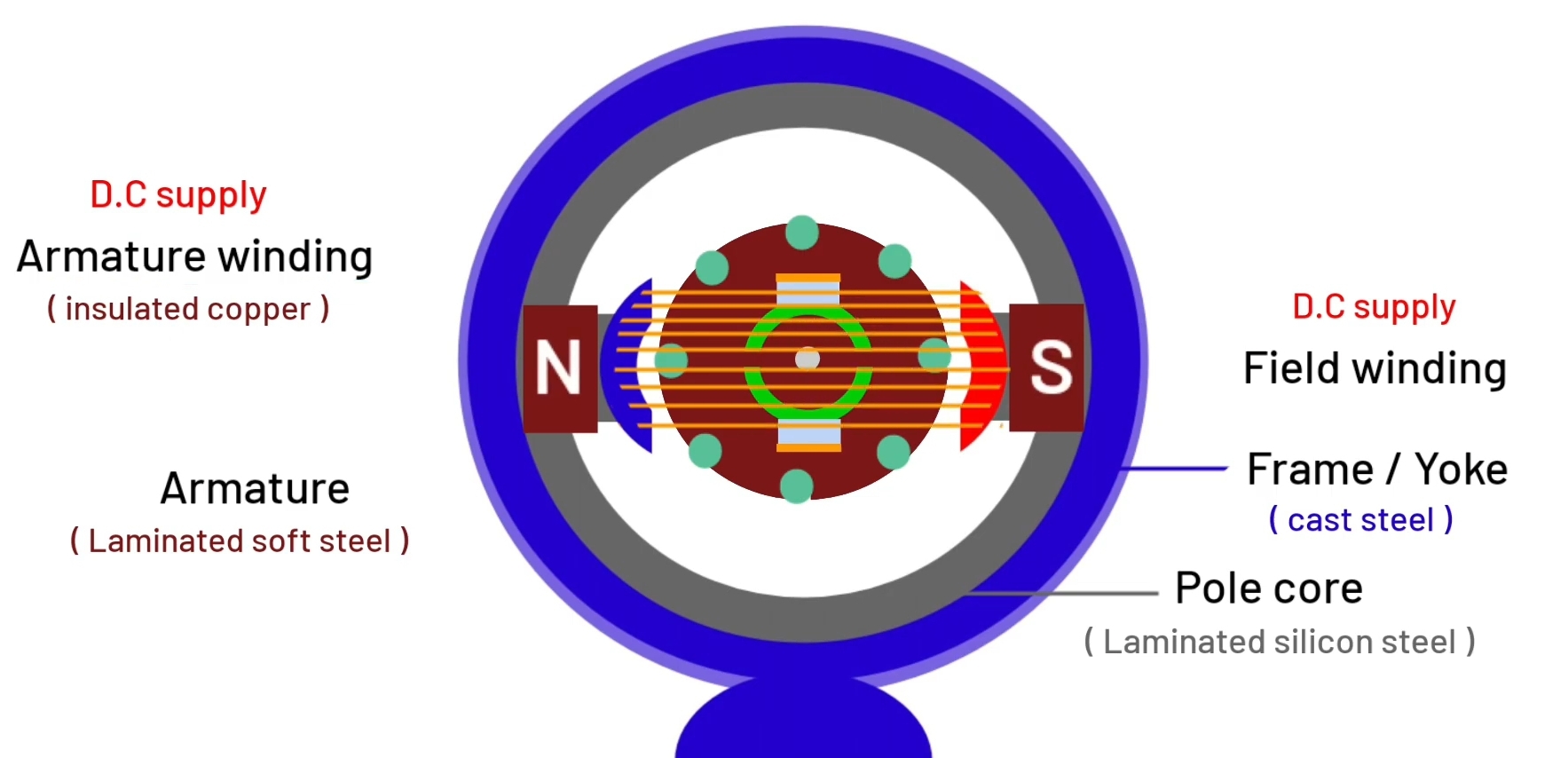

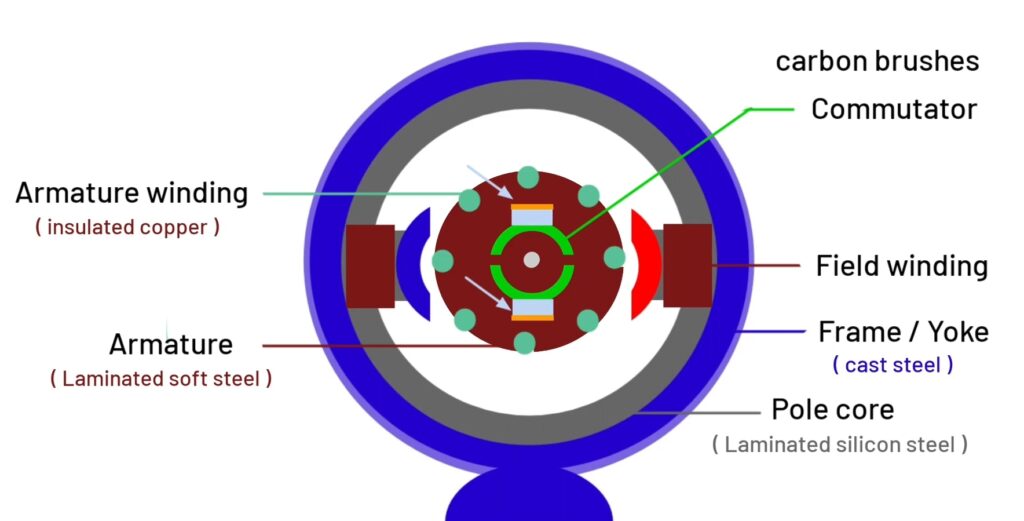

Stator : stator is the stationery part of DC motor it will remain fix at one place it will not move or rotate. stator core is made up of laminated Silicon Steel that supports magnetic field lines due to high permeability property .

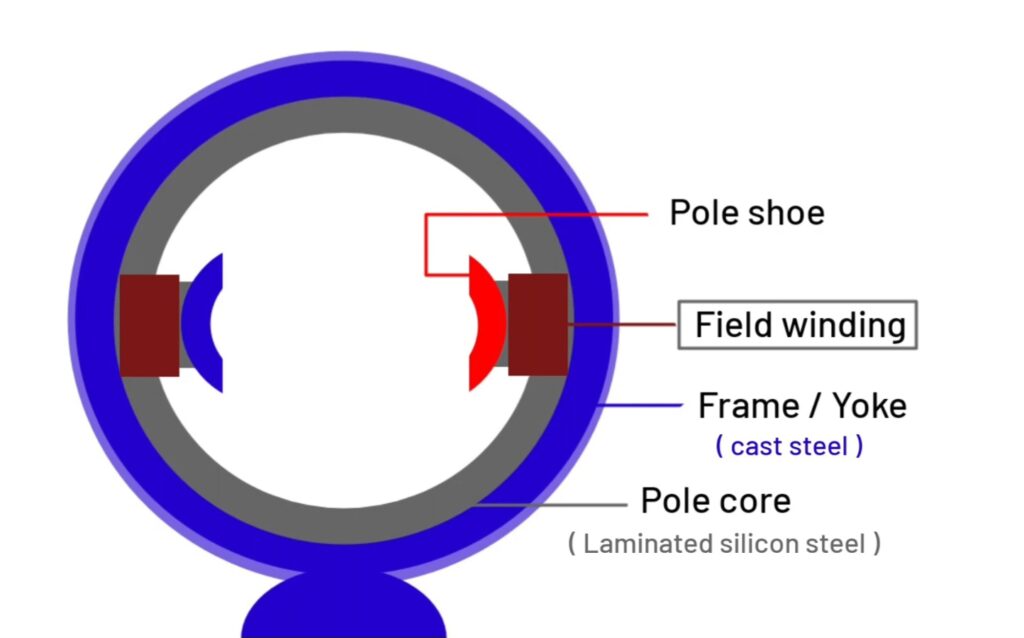

Frame : frame is also known as yoke that supports the stator core and protect the internal assembly of the DC motor , it provides easy path for magnetic flux that will produced by field winding placed on field pole. Outer frame of DC Motor is made up of cast steel .

Pole : poles are present at the inner portion of a stator where field winding remain placed . This portion of pole is known as pole shoe that supports the field coil . DC motor working principle also reducing the reluctance of magnetic path by increasing the area , due to more space reluctance of magnetic path get reduced .

Field winding : field winding place on field pole at inner portion of a stator core.

Armature : armature is the rotating part of DC motor , armature core is also made up of laminated soft Steel lamination is the arrangement of various thin sheets were all lamination sheets are insulated by the coating of varnish and clamped together. Armature of motor is also known as roto that placed on shaft . Insulated copper conductor place on the outer portion of armature. That play very important role in the DC motor working principle and it is known as armature winding. To insulate the winding varnish material is used we provide coating on armature winding

there are two type of windings are used on armature that is either lap winding or wave winding

Commutator : commutator is the important part of armature that behave like mechanical rectifier. Carbon brushes are attached with commutator. We give dc supply in armature by the help of commutator and carbon brushes. Commutator is the copper segment where each segment is connected to end of the armature coil. Construction of DC motor is just like DC generator but working of both machine is different. DC motor convert DC electrical energy into mechanical energy while DC generator converts mechanical energy into DC electrical energy

dc motor working principle

First of all we give DC supply to the field winding that place on stator pole so due to DC supply and inductive copper winding constant magnetic field produces.

and as well as we innergize the armature winding with DC supply through commutator and carbon brushes . So according to working principle of DC motor from lorentz law “whenever current carrying conductor placed in magnetic field conductor experience electromagnetic force in tangential direction” here also current carrying armature is placed in magnetic field produced by field winding so torque acts on the armature conductor in tangential direction and armature starts to rotate where direction of rotation is determined by Fleming left hand rule .

commutator and brushes plays very important role in dc motor working principle , it reverse the current at half rotation so that armature rotate in same direction. This is dc motor working principle

Back EMF in dc motor

during operation of DC motor when armature cuts the stationery magnetic field then EMF induces due to generator action where produced back EMF opposes the supply voltage . When are major

rotates and cuts the constant magnetic field produced by field winding self EMF induces in the armature conductor from Faraday’s law of electromagnetic induction. And induced EMF opposes the supply voltage in dc motor.

magnitude of back EMF is given by

Eb = NPØZ/60 A

- Eb – back emf

- A – number of parallel path

- P – number of poles

- N – speed of armature

- Z – total number of conductor in armature