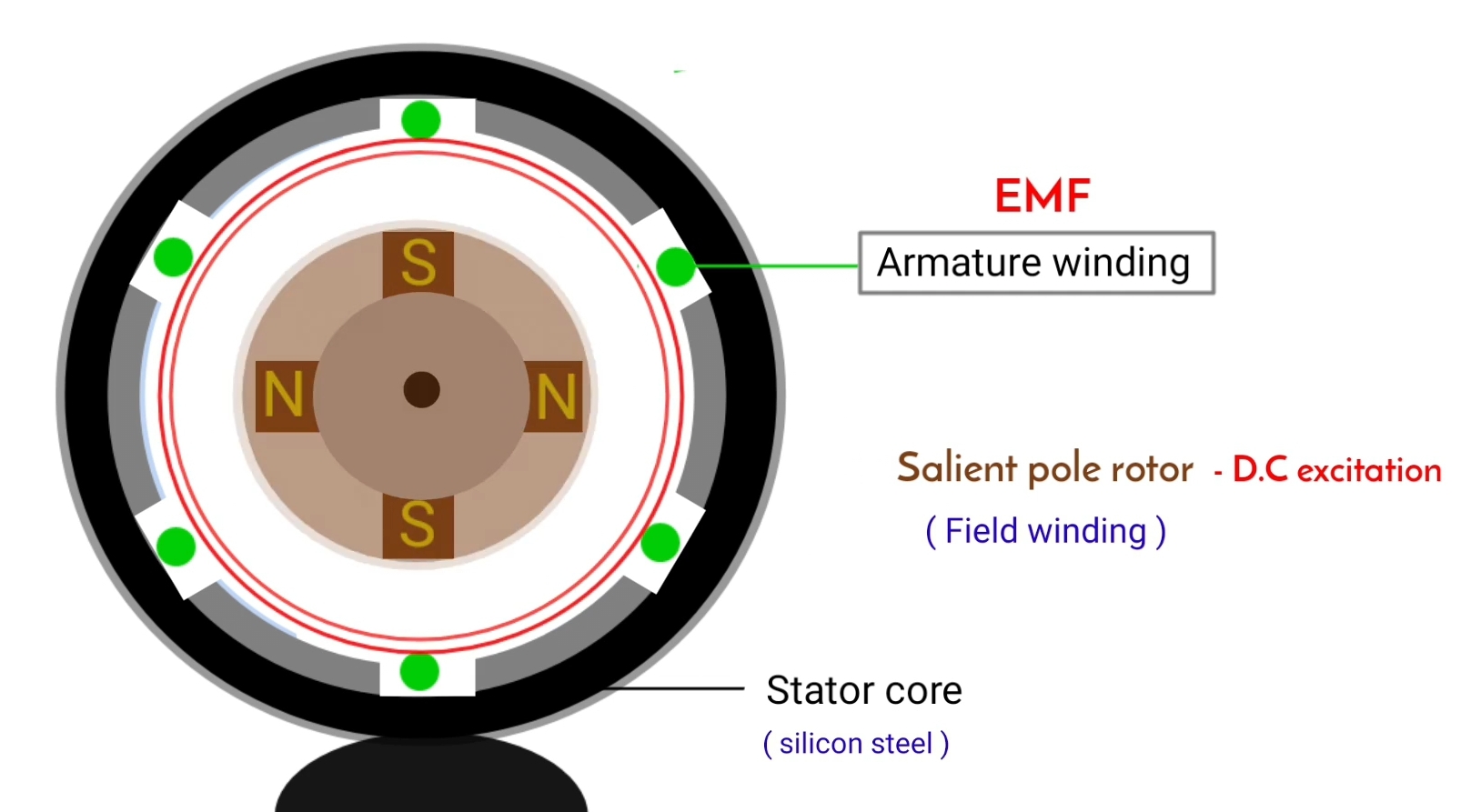

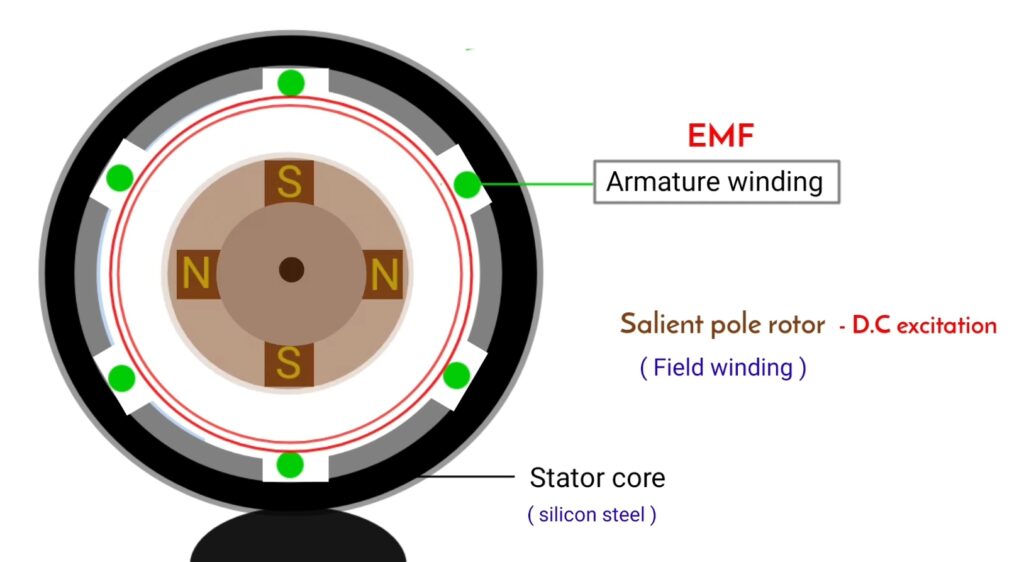

Alternator is electrical machine that is also known as synchronous generator that converts mechanical energy into electrical energy . consist with two important parts rotor and stator , stator is the stationary part of machine, whereas rotor is the rotating part of the alternator. In case of alternator , armature winding placed on stator and field winding placed on rotor . that play very important role in alternator working principle.

Construction

Stator :

stator is the stationery part of alternator.

Frame : At the outer portion of a stator frame is placed that protect the element of alternator from damage. In small size alternator frame is made up of cast iron but in big size alternator welded type steel is used.

Stator core :

core of alternator is made up of silicon steel that provide high permeability and low reluctance path for the magnetic field lines. and core consist with various thin strips that joined together to make stator core that is known as lamination, laminated core reduces the eddy current loss in alternator working principle. Slots are present at the inner portion of a stator core. where three phases winding is placed that connected in a star connection.

Rotor :

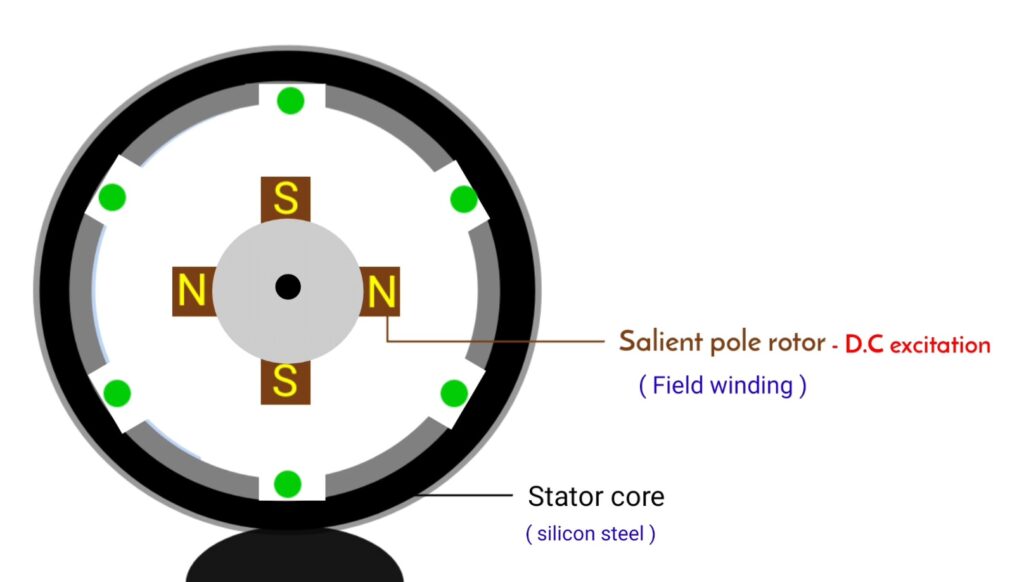

there are two types of rotor is used in alternator ( salient pole rotor & cylindrical rotor )

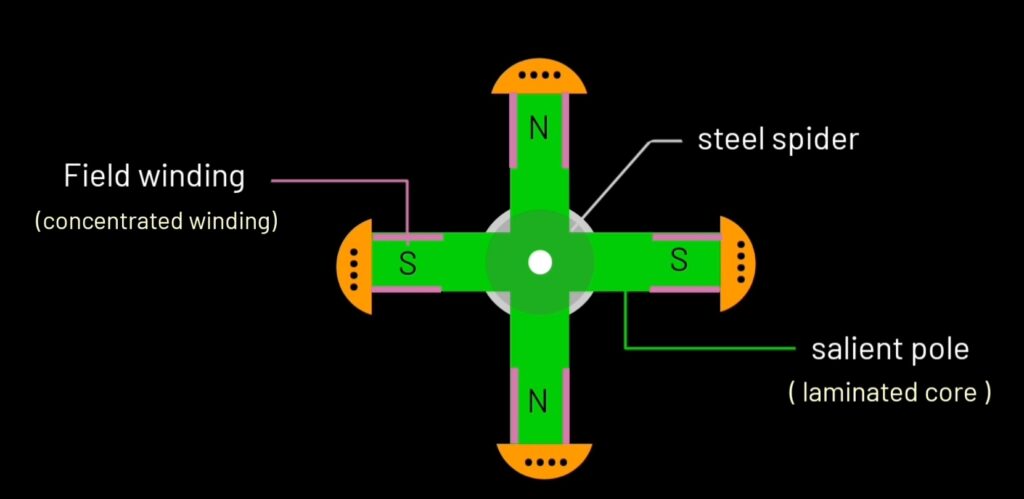

Salient pole rotor :

Salient pole rotor consist with salient poles , pole remain projected outward with non uniform gap. Steel spider is used to connect the projected poles together. Concentrated type winding is placed in salient pole rotor because it has non uniform gap. As I write in definition in case of alternator synchronous generator field winding placed at rotar. Rotar is also made up of laminated Silicon steel to reduce eddy current loss in alternator working principle.

damper bars are provided at the pole face of salient pole rotor that damps the oscillations created by non uniform gap. Oscillations occur in alternator due to sudden in load .

Alternator working principle

we give DC excitation in field winding by the help of slip ring and brushes. So constant magnetic field produces on rotor poles due to DC current.

now we give mechanical input to the rotor by external prime over, here I am considering steam turbine as prime over. So shaft of a steam turbine attached to alternator rotor shaft , and when steam turbine rotates then salient pole rotor of alternator also rotates by receiving mechanical energy.

when rotor rotates then constant magnetic field also rotates created by DC current and when constant pole rotates then it creates rotating magnetic field and when rotating field link with armature winding place on stator then EMF induces in the armature winding due to relative motion between rotating magnetic field and constant armature conductor from Faraday’s law of electromagnetic induction.

according to Faraday’s law of electromagnetic induction whenever changing magnetic field link with stationery conductor then EMF induces in the conductor or it’s vice versa . Alternator working principle is based on electromagnetic induction

and due to complete circuit of armature winding with load , current starts to flow in the armature winding towards the load. And nature of that generated current is alternating / A.C current. And direction of current will determine by Fleming right hand rule. This is alternator working principle.

Important points

- induced EMF in armature winding of alternator is directly proportional to a speed of rotor RPM , coupled with prime mover.

- to achieve Desire frequency we have to rotate rotor at the particular speed with the help of Prime mover that we can find by the equation of ( Ns = 120 F / P ) where , (Ns) is the synchronous speed , (F) is the frequency & (P) is the number of poles .

- Suppse we have 4 pole rotor and 50 hz required, then value of frequency and no of poles will put in above equation so ( Ns = 120 × 50 / 4 ) = 1500 RPM . So when we rotate the rotar at 1500 RPM then we can achieve 50 hertz frequency .