capacitor start induction run motor is the type of single phase induction motor in which capacitor is used to start the motor . As the name suggest capacitor start motor, so it’s clearly shows that capacitor will help to start the motor. Capacitor start induction run motor is used to convert electrical energy into mechanical energy, just like other induction motors.

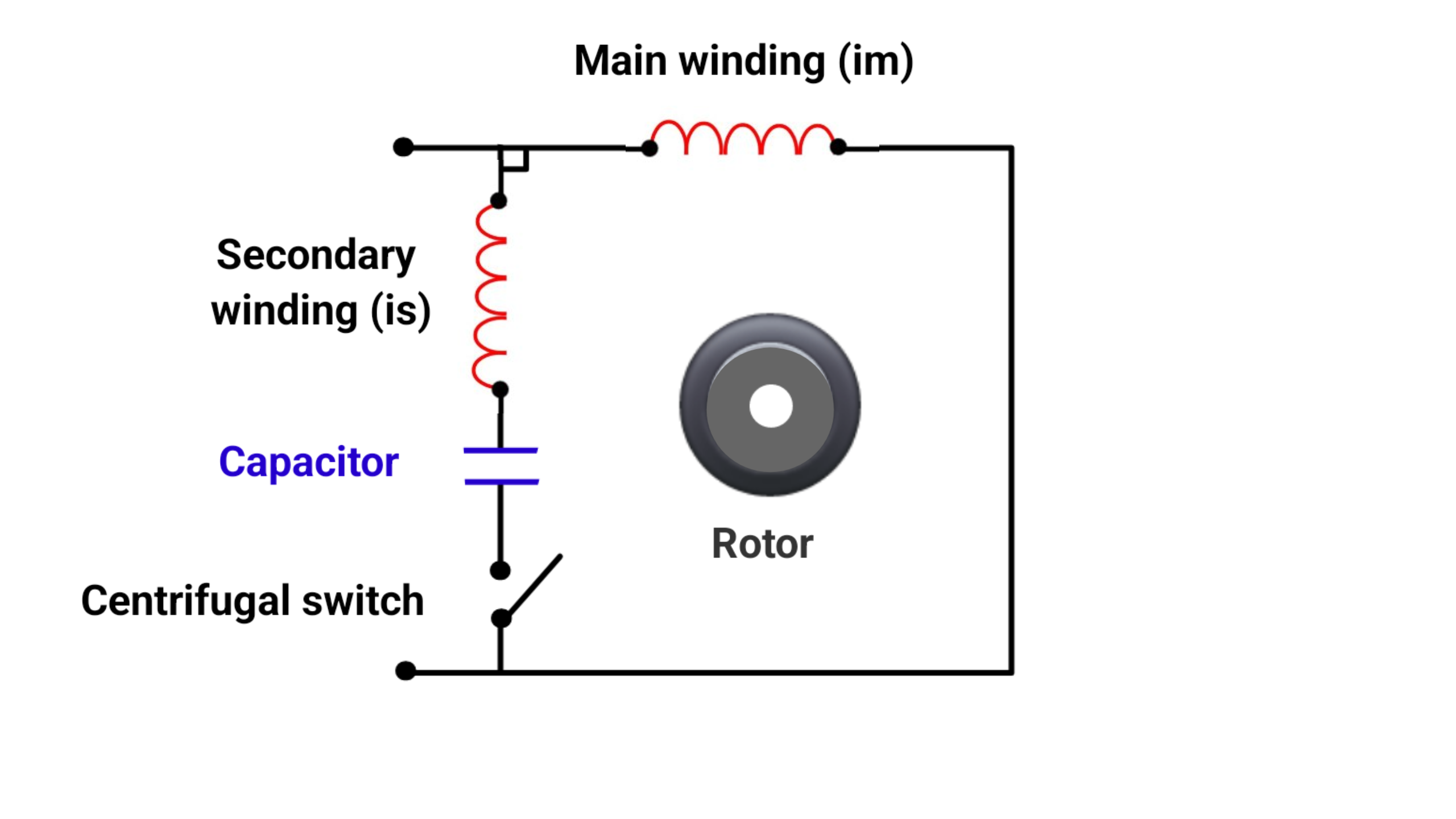

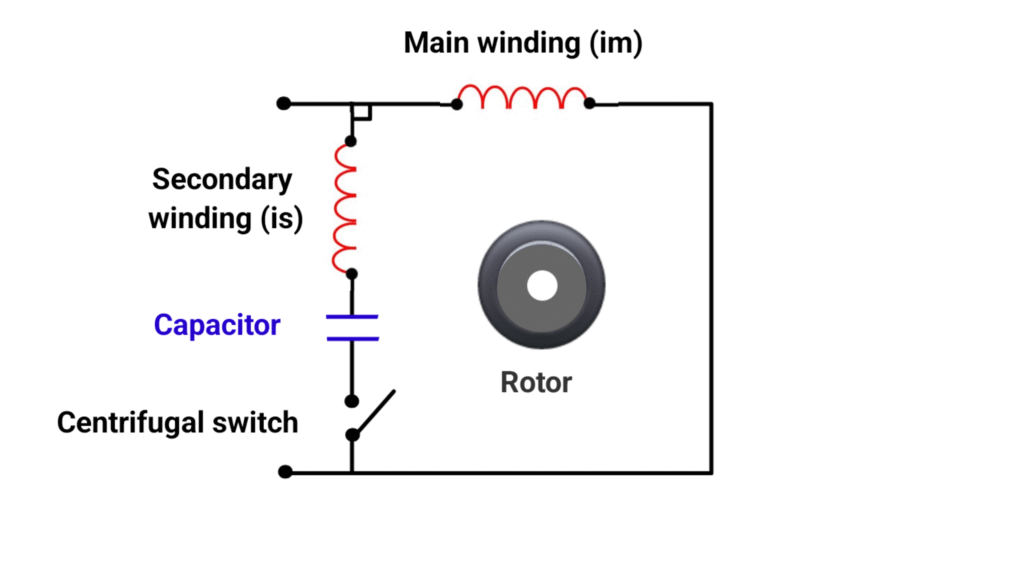

Connection diagram of capacitor start induction run motor

cage type rotor is used in capacitor start induction run motor . Two types of winding are placed on a stator , starting winding and main winding that is also known as auxiliary winding and running winding. A capacitor is connected in series with a starting winding that is used to start the motor by creating phase difference between starting winding and main winding . it’s construction is almost similar like split phase induction motor.

main difference between capacitor start induction run motor and split phase induction motor , in capacitor start induction motor, we use starting capacitor. That helps to create the phase difference and starts the motor. A centrifugal switch is connected in series with starting winding. Main function of centrifugal switch when motor reaches the required speed or motor starts to rotate at maximum speed.

Then it disconnect the starting winding and runs continuously with main winding. Starting winding and main winding, both are displaced by 90° . centrifugal switch is electrical device that is used to disconnect the starting winding after reaches the motor speed about 70% .

Working principle of capacitor start induction run motor

First, we give single phase AC supply in capacitor start induction run motor , when current flows in the circuit, then at the portion of displacing angle of both winding current splits in two parts one current flows in main winding and another one flow in auxiliary winding . Suppose supply current is (i) that is a splitting into two direction (im) and (is) , current in main winding is denoted by (im) and current in a starting winding is denoted by (is) .

In this circuit, main winding remain highly inductive, and due to highly inductive nature current in main winding, that is, (im) lags by voltage . Whereas starting winding remain highly capacitive due to capacitor connected in series with starting winding . And due to capacitive nature of starting winding , current in starting winding that is (is) leads by supply voltage (v) by angle nearly 90° so due to phase difference between both winding rotating magnetic field produces in the gap of rotor and stator .

Since phase difference between both winding is less than 90°, but rotating magnetic field produced in air gap produces enough torque to rotate the rotor . When motor speed reaches about 70 to 80% of their full speed then a starting widening get disconnected by the help of centrifugal switch . And motor runs continuously with the help of main winding.

Phasor diagram of capacitor start induction run motor

First of all, we take reference as supply voltage (v) current in starting winding (is) leads by voltage (v) due to capacitor connected in series with starting winding . And current in main winding (im) lags by supply voltage (v) due to highly inductive nature of main winding . So phase difference created between (im) and (is) is denoted by Alpha .

And total current (I) will of obtain by phasor sum of current in main winding (im) and current in a starting winding (is) , total current is the Phasor addition of current in main winding and current in starting winding . Due to this total current RMF or rotating magnetic field produces in the air gap of a stator and rotor that act torque on the rotor .

characteristics of capacitor start induction run motor

- the starting torque of this motor is much higher about 3 to 4 times of full load torque

- the starting capacitor value must be large

- the value of a starting winding resistance must be low

according to characteristics of capacitor start induction motor starting torque is high this type of single phase induction motor has high cost as compare to a split phase induction motor due to extra cost of capacitor that connected in series with starting winding. Capacitor start induction run motor can be reversed by reversing its terminal in starting.

n0 showing the point after that starting winding or auxiliary winding, get disconnected by the help of centrifugal switch. after that motor continuously runs with the help of main winding or running winding.